ProboStat CMR Catalytic Membrane Reactor

Introduction

Dense ceramic or metallic as well as microporous ceramic membranes find potential applications for separating oxygen from air, hydrogen from syngas, and CO2 from flue gas, all of importance in various energy technologies for reduced CO2 emissions from use of fossil fuels. In addition they may be applied in oxidation / reduction or hydrogenation / dehydrogenation processes. They may be used as a standalone membrane (MR reactor) or in intimate combination with a catalyst (CMR). In the latter, the membrane may effectively remove or add a reactant, shifting the thermodynamic equilibrium and yielding the yield and / or selectivity.

Many membranes operate at elevated temperatures, especially dense ceramic membranes utilizing the superior selectivity from gas permeation by ambipolar transport of ions and electrons. For these, tubular membranes - usually having the dense membrane as a thin film supported by a porous main structure ("asymmetric membranes") - offer a good alternative to more space-efficient monolithic or planar layered membrane assemblies during laboratory test and proof-of -concept stages. The main virtues of the tubular setup are possibility of cold seals, easy replacement of tubes, and relatively simple geometric approaches to integration with a catalyst and gas flow and analysis.

However, construction of such laboratory setups for tubular (as for other) membrane geometries is time-consuming and expensive, and there has been a lack of standards and commercial products. The NorECs ProboStat sample holder system for electrical characterization at high temperatures and in controlled atmospheres has gained widespread use and acceptance, and is now available for more optimized catalytic membrane reactor tests.

Normal ProboStat

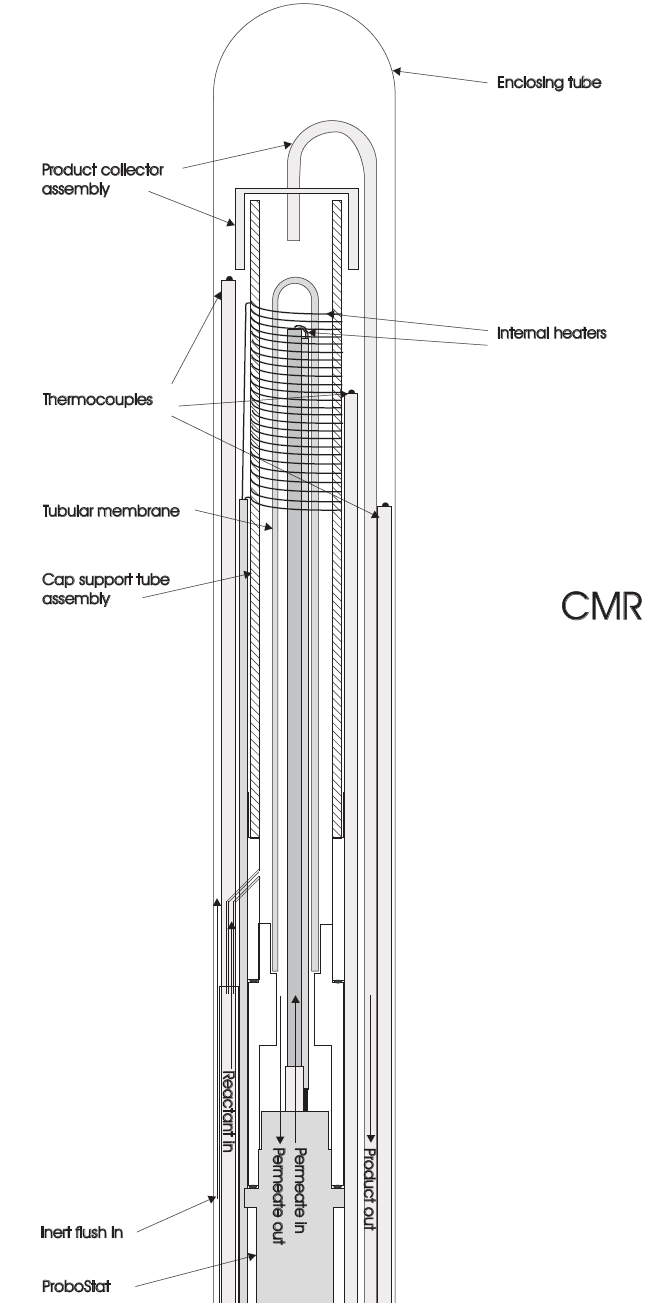

A ProboStatTM is a sample holder which can accommodate a disk membrane supported and sealed on top of a support tube in the hot zone, or a tubular membrane closed in the high temperature zone, and sealed otherwise to the sample holder in the cold zone. The support tubes or membrane tubes are sealed to a pedestal and forms an inner chamber, while an outer enclosing tube forms an outer chamber. With a normal version of ProboStatTM, each of the two chambers has two gas connections (in and out - total of four) and a number of electrical feedthroughs (4 for the inner and 12 for the outer). These feedthroughs can be used for electrodes, thermocouples, and internal ohmic heaters, as well as oxygen sensors. The ProboStat is suitable for electrical measurements on samples of many geometries and - the focus of this note - of permeation through disk or tubular membranes.

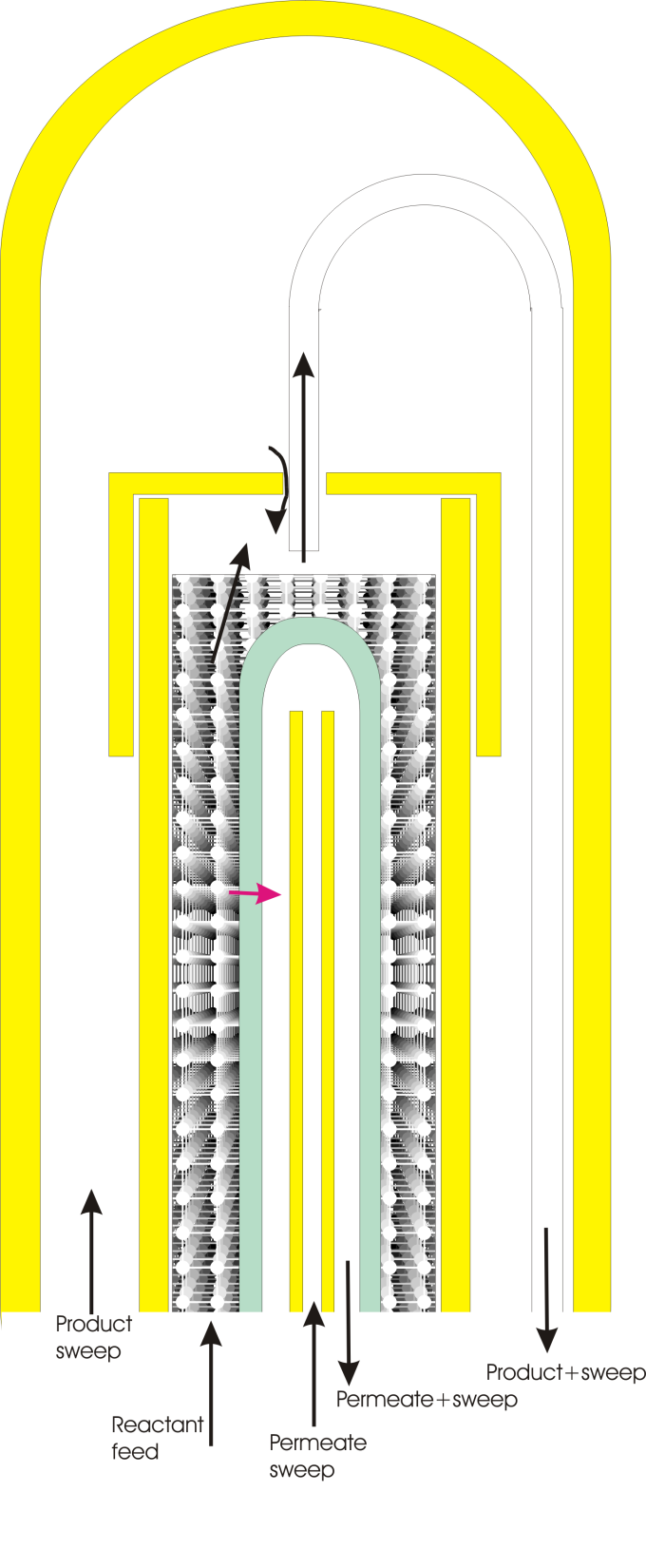

The figures below show schematically three different setups with tubular membranes. The two to the left show a closed medium-sized tubular membrane with a gas flushing tube inside. The photograph shows the base unit and the membrane tube, while the schematic also shows the inner flushing tube and an outer enclosing tube. Flushing tube for the outer chamber can be used in the figures, for simplicity. The third figure shows the membrane tube instead of the thin innermost tube, and the medium-sized open ended tube serving for guiding the gas flow along the membrane side. The rightmost figure shows this guiding tube filled with a catalyst to make it work as a catalytic membrane reactor. The catalyst can also be placed on the surface (s) of the membrane tubes in the other two setups.

This is one example of how one may use the ProboStatTM CMR. The user may find ways to use the 5 gas connections and make custom sockets for his tubes.

The left hand figure above shows the winding of an internal ohmic heater (Pt10Rh) around the active membrane area. The use of this helps to reach the operating temperature in the hot part of the membrane while using less power in the tube furnace around the cell. This helps to prevent overheating the neck of the base unit and the seals of the tubes to that part. It is possible to also use a small ohmic Pt10Rh heater inside the membrane tube to help reduce the temperature gradient between the membrane outside and inside. Thermocouples may be placed at several locations to monitor temperatures and gradients.

Things to take into account

The ProboStat and especially the ProboStat ™ CMR are very versatile and provide many possibilities of setting up permeation and other experiments. All parts in the hot zone may be replaced easily and may be ordered in standard or custom dimensions and materials from NorECs or made by the customer. We and the manual help with dimensions and advice for the latter. But ProboStatTM and - because of its typically demanding uses - ProboStatTM CMR also have their limitations and challenges. The setups can be so complex and based on the user's tubes and dimensions that the user must take responsibility for him self understanding how the measurements and measurements are performed and that the dimensions of ceramics are within bounds.

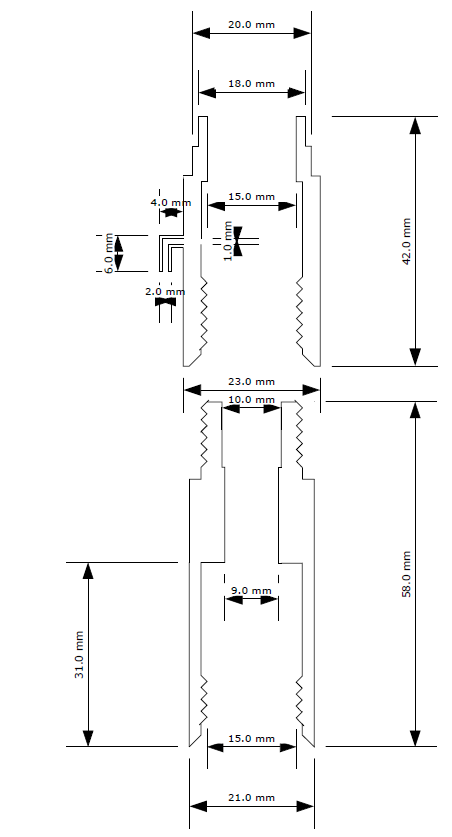

The dimensions on the tubes are particularly important. The length should ideally be at least 30 cm; for instance 5 cm cold, 10 cm transition zone, and 15 cm hot zone. With shorter tubes, one must compromise; the cold zone may get too hot and shorter lifetime of seals and parts. The transition zone gets short and puts strain on the tubes. And the hot zone gets shorter and potentially less homogeneous.

Short tubes can be extended with raiser tubes of metal or ceramic, but this requires the use of a hot seal.

The thickness of tubes is also critical. The inner space of the ProboStat ™ enclosing tube is some 30 mm in diameter. This limits the outer diameter of the membrane and middle tubes. Ideally a membrane tube is around 10 mm outer diameter. Likewise, the inner diameter of the membrane tubes should not be too small, because then gas flushing tubes, heaters, and thermocouples can not all fit in.

Tube straightness and correct alignment during gluing is also important if the tubes are long, since several tubes run inside each other.

All in all - the setup of normal ProboStatTM membrane permeation tests with tubular membranes is quite straightforward unless the tubes are too short, while the additional possibility of the 5th gas of the CMR version requires more careful thinking of the diameters and other details. We need the customer to get the best possible parts, but the customer must take responsibility for understanding what he wants to set up.

Parts in the hot zone such as ohmic heaters may have limited lifetime. They may be repaired by the user, or ordered from Norecs.

A ProboStatTM CMR may be used as a normal ProboStatTM for permeation and catalytic tests by using the 5th gas connection and using the normal rather than the CMR socket.

In a special version, all normal electrode feedthroughs are replaced with compensation wire so as to allow an increased number of thermocouples in the hot zone - 7 in total.

These articles refer to ProboStat or other NORECS products, with keywords: 'CMR'

Direct conversion of methane to aromatics in a catalytic co-ionic membrane reactor

Authors: S.H.Morejudo, R.Zanon, S.escolastico, I. Yuste-Tirados, H. Malerød-Fjeld, P.K. Vestre, W.G.Coors, A.Martinez, T.Norby, J.M.Serra, C.Kjølseth

Source: Science, Volume: 353, Issue: 6299, Pages: 563-566

Publisher: American Association for the Advancement of Science (AAAS), ISBN: Print ISSN: 0036-8075 Online ISSN: 1095-9203, Time of Publication: 2016-08

Abstract: Nonoxidative methane dehydroaromatization (MDA: 6CH4 ↔ C6H6 + 9H2) using shape-selective Mo / zeolite catalysts is a key technology for exploitation of stranded natural gas reserves by direct conversion into transportable liquids. However, this reaction faces two major issues: The one-pass conversion is limited by thermodynamics, and the catalyst deactivates rapidly through kinetically favored formation of coke. We show that integration of an electrochemical BaZrO3-based membrane exhibiting both proton and oxide ion conductivity into an MDA reactor gives rise to high aromatic yields and improved catalyst stability. These effects originate from the simultaneous extraction of hydrogen and distributed injection of oxide ions along the reactor length. Further, we demonstrate that the electrochemical co-ionic membrane reactor enables high carbon efficiencies (up to 80%) that improve the technoeconomic process viability. Methane gas is expensive to ship. It is usually converted to carbon monoxide and hydrogen and then liquefied. This is economically feasible only on very large scales. Hence, methane produced in small quantities at remote locations is either burned or not extracted. A promising alternative is conversion to benzene and hydrogen with molybdenumzeolite catalysts. Unfortunately, these catalysts deactivate because of carbon buildup; plus, hydrogen has to be removed to drive the reaction forward. Morejudo et al. address both of these problems with a solid-state BaZrO3 membrane reactor that electrochemically removes hydrogen and supplies oxygen to suppress carbon buildup.

Keywords CMR, MDA, catalytic membrane reactor, ZSM-5, MCM-22, FBR, FBR-PolyM, Pd-CMR, Co-ionic CMR, FT, ProboStat CMR base unit (NorECs)

BaZrO3 Link