- Home

- Who We Are

- Products

-

Brands

-

Products by Measure

- Vibration Analyzers

- Peristaltic Pumps

- Airflow

- CO Carbon Monoxide

- Geiger counters

- Destiladores

- Spectrophotometry

- Sterilization

- Fluorescence

- GEOTECHNICS

- Soil Moisture

- Leaf area index

- Rain Gauge

- Meteorology

- Water Level

- O2 Oxygen

- pH

- Differential Pressure

- Radiation

- Salinity/Conductivity

- Telemetry

- Air Speed

- Relative Humidity

- Veterinary

- FUEL CELL HARDWARE

- Network Analyzers

- Calibrators

- WATER FLOW

- Color / Colorimeter

- Particle Counters

- Wind Direction

- Spectrometry

- Evapotranspiration

- Photosynthesis

- Cracks in Buildings

- Pipes Inspection

- Quantum Light

- Movement & GPS

- Diesel Level

- Oxígeno Disuelto DO

- Atmospheric Pressure

- Radon

- Sap/Sap Flow

- Temperature

- AIR QUALITY

- Ammonia

- Chlorophyll

- Conductivity in Soil

- Dendrometers

- Electrochemistry

- Spectroradiometry

- Pharmacy & Medicine

- GAS (ANALYZERS)

- Leaf Wetness

- Idc (DC Current)

- KW & KW/H

- PAR Light

- Nitrate

- Occupation and Time

- Particle Meters

- Soil Water Potential

- Pulses

- Flavor/Taste/Acidity

- Sodium

- Turbidity

- VOC

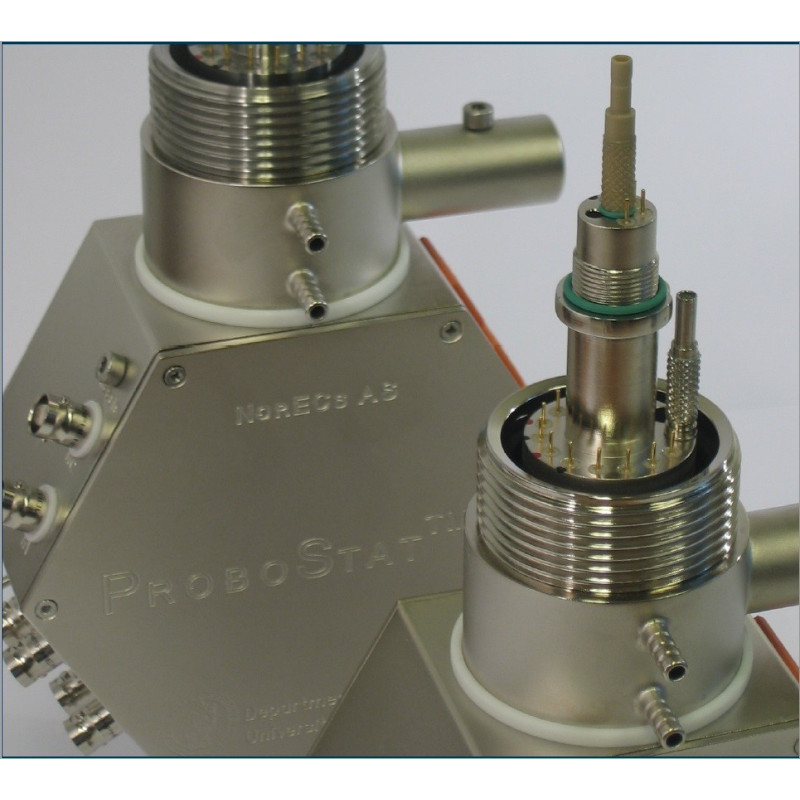

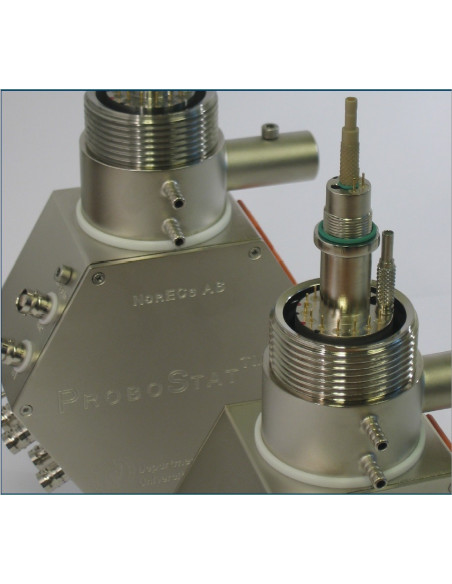

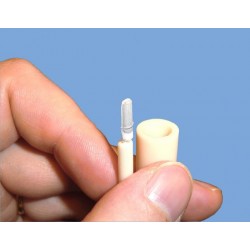

ProboStat-Heating-Systems Base Unit

Prevent undesirable proceses inside the ProboStat gas lines

'Base unit heating system, 165 ºC' helps the user in heating of the gas lines of cold zone parts of the ProboStat.

In an experiment, the hot zone is inside a furnace at target temperature. Desired gases are supplied to the sample area through gas connects on the base unit. For some gases from the gas source to the sample (and/or back) a minimum temperature is required to avoid condensation of water or organic vapors in the cold zone of the ProboStat base unit. The base unit heating system is an addition to ProboStat base unit that helps heating and controlling the cold regions.

The base unit heating system provides feedback of temperatures in the top box in form of additional K-type thermocouples installed inside the unit. In addition a heater unit and insulation are installed to the base unit hexagon. The thermocouple voltages are read by the user and interpreted, and the area temperature is controlled with included adjustable power supply. Depending of the operating conditions the flange area may be susceptible to low temperatures, and may require external insulation or external heating. By monitoring the thermocouple located at the area of the flange the temperature inside will be known and appropriate action can be taken.