Probble Fuel Cell Test Safety Device

Many small laboratory applications such as fuel cell tests, membrane tests, or annealing furnaces, need a moderate flow of a gas of a certain composition, delivered at near atmospheric pressure. In some cases the gas needs to be dry, in some cases humidity does not mater, and in some cases the gas needs to be humidified.

Probble is a water-filled plastic container with gas flow connections that primarily allows one to humidify the gas while maintaining a small constant overpressure suitable to safely drive the gas through an apparatus like a fuel cell chamber or annealing furnace tube. Secondly it provides safety overpressure release in case the following apparatus becomes closed. Thirdly and optionally it allows separate overpressure regulation and flow visualisation of return gas, useful for verification of apparatus function and gas tightness. In the case of use with fuel cells or other dual chamber applications, two Probbles allow individual adjustment of over-pressures and thus can help monitor and minimise effects of sealing leakage.

Inadvertent closure or clogging of the gas flow in the application may lead to risk of overpressure buildup. This is especially dangerous in the case of use of homemade humidifiers based on glass bottle bubblers. Professional and commercial fuel cell test stations with humidifiers take care of these things, but are often excessively expensive and sometimes provides too coarse control of overpressure ainnd of pressure differences between cell chambers in fuel cells and other small and sensitive membrane test setups.

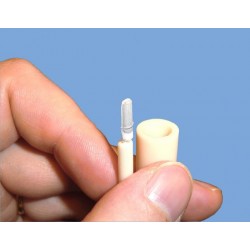

The 'Probble' provides a simple, safe and inexpensive alternative and solution. It makes use of one volume of liquid water for both humidification, overpressure safeguarding, pressure difference control, and flow visualisation. It utilises materials and construction that make the device simple, safe, and affordable. The central part is what we may refer to as a double bubbling tube. The pressures involved are close to ambient atmospheric (1 atm) and the humidification not higher than room temperature dew point (ca . 3 % H2O, or pH2O ~ 0.03 atm).

The 'Probble' comes as part of the FCMix gas control system for small fuel cells, but is also sold separately. Contact NorECs for an enquiry.

Background

The humidity may be required because it is an essential part of the atmosphere, such as in annealing to hydrate materials or in chambers for biological material that must be prevented from drying out. It may furthermore be necessary for humidification of the fuel in many types of fuel cells, to avoid anode embrittlement or coking. For tests of proton conducting fuel cells it may be needed both for the anode and cathode gases (fuel and oxidant). It may in other cases be an important part of the atmosphere because it emulates real operating conditions, e.g. in ambient (humid) air. The pressure is often required to be near-atmospheric because the laboratory apparatus is not designed for any degree of overpressures. Especially, the use of ceramic enclosures for high-temperature operation or plastic or glass enclosures for ambient temperature operation, or simply safety, are reasons for operation at near-atmospheric pressure.

Humidification can be done by bubbling the gas through water, or for instance by evaporating a stream of liquid water into the gas by a heated spray inlet or by letting the water permeate a polymer membrane. Many commercial devices for this purpose employ high temperatures in order to accomplish water vapour contents up to dew points of 100 °C (1 atm H2O). Overpressure safeguarding and pressure control can be done by mechanical fore- or backpressure regulators. Bubbling excess gas over non-volatile liquids such as mercury, oil, or dibutyl phthalate is another, finer option. Control and indication of gas flow can be important for quantitative inspection and evaluation of the operation of apparatus, but also for qualitative indication of main operational parameters of the cell being studied. An example is the flow through the chambers of a fuel cell or gas separation membrane reactor that indicates that the cell chambers are properly sealed and that the in- and outlets are not blocked by e.g. condensed water, coke, or tar.

Problems of existing technology (prior art)

Problems with existing technologies and products can be classified into two groups: Commercial systems for humidification and pressure/flow control, for instance for fuel cells, are oversized for small and laboratory applications: Regulation of pressures – both the total pressure and the possibility to vary small pressure differences between the two cell chambers – are too coarse. This is typically a result of mechanical pressure regulators that cannot maintain very small pressure gradients. It may also be a result of thermal mass flowmeters and controllers that are designed for certain pressure ranges. The resulting pressure differences and changes in pressure may easily break thin, fragile ceramic sample membranes or press open many types of sealing. For other, simpler, uses, like simple supply of gas to a reaction, annealing, or sintering furnace, a commercial gas supply unit may be suitable and functional, but often considered too expensive. To conclude on this group, commercial systems are often too coarse for certain purposes, and too expensive for many users.

The other group of problems concerns users who build a home-made system for humidification and control of gas flows. Their decision to do so may have economical reasons, but it may also result from the desire to avoid the too rough controls of oversized commercial systems. The homemade systems may then suffer from hazards due to insufficient safety against overpressure build-up and use of glass apparatus that may break or explode. It may furthermore lack fine controls or visualisation of pressure and flow.