- Home

- Who We Are

- Products

-

Brands

-

Products by Measure

- Vibration Analyzers

- Peristaltic Pumps

- Airflow

- CO Carbon Monoxide

- Geiger counters

- Destiladores

- Spectrophotometry

- Sterilization

- Fluorescence

- GEOTECHNICS

- Soil Moisture

- Leaf area index

- Rain Gauge

- Meteorology

- Water Level

- O2 Oxygen

- pH

- Differential Pressure

- Radiation

- Salinity/Conductivity

- Telemetry

- Air Speed

- Relative Humidity

- Veterinary

- FUEL CELL HARDWARE

- Network Analyzers

- Calibrators

- WATER FLOW

- Color / Colorimeter

- Particle Counters

- Wind Direction

- Spectrometry

- Evapotranspiration

- Photosynthesis

- Cracks in Buildings

- Pipes Inspection

- Quantum Light

- Movement & GPS

- Diesel Level

- Oxígeno Disuelto DO

- Atmospheric Pressure

- Radon

- Sap/Sap Flow

- Temperature

- AIR QUALITY

- Ammonia

- Chlorophyll

- Conductivity in Soil

- Dendrometers

- Electrochemistry

- Spectroradiometry

- Pharmacy & Medicine

- GAS (ANALYZERS)

- Leaf Wetness

- Idc (DC Current)

- KW & KW/H

- PAR Light

- Nitrate

- Occupation and Time

- Particle Meters

- Soil Water Potential

- Pulses

- Flavor/Taste/Acidity

- Sodium

- Turbidity

- VOC

MSC1 Air Conditioning and Climate Control System Training Board (System with Orifice Tube)

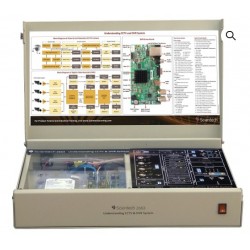

The MSC 1 training board-simulator is a great educational tool that allows students to learn the structure of air conditioning and climate control system, study its components, and perform various measurements, tests and other diagnostic procedures to use diagnostic scan tools or other special tools and equipment.

Price on request.

MSC1 Air Conditioning and Climate Control System Training Board (System with Orifice Tube)

I accept privacy policy rules

Fully functional air conditioning and climate control system trainer is installed in a mobile aluminium frame. This training board – simulator is specially designed to help technical students understand better electronic air conditioning and climate control system CLIMAtronic. The educational training board is based on Audi/VW OEM components. The integrated air conditioning and climate control system shows the different operation modes.

- Diagnostic and measurement

Oscilloscope/multimeter

- System‘s parameters are measured by connecting to the banana connector;

- Ability to measure electrical signal parameters of each system component (such as sensor or actuator)

Control unit diagnosis (with the scan tool)

- Diagnosis through OBD 16 – pin diagnostic connector

- Electronic control unit (ECU) identification

- Reading/erasing fault codes

- Displaying the operating system parameters (live data)

- Activating the actuators (depends on the control unit)

- Control unit encoding/configuration (depends on the control unit)

Control unit diagnosis (manual procedures without the scan tool)

- Manual diagnostics of Climatronic ECU

- Error reading – manual procedures

- Displaying the operating system parameters (live data) – manual procedure

- Optional accessories

- Automotive oscilloscope

- OBD Diagnostic scan tool

- Air conditioning recharge station

• Integrated electronic air conditioning system with climate control (Climatronic)

• Monitoring operation modes of air conditioning and climate control system

• Visible HVAC compressor, electromagnetic compressor clutch and its operation modes

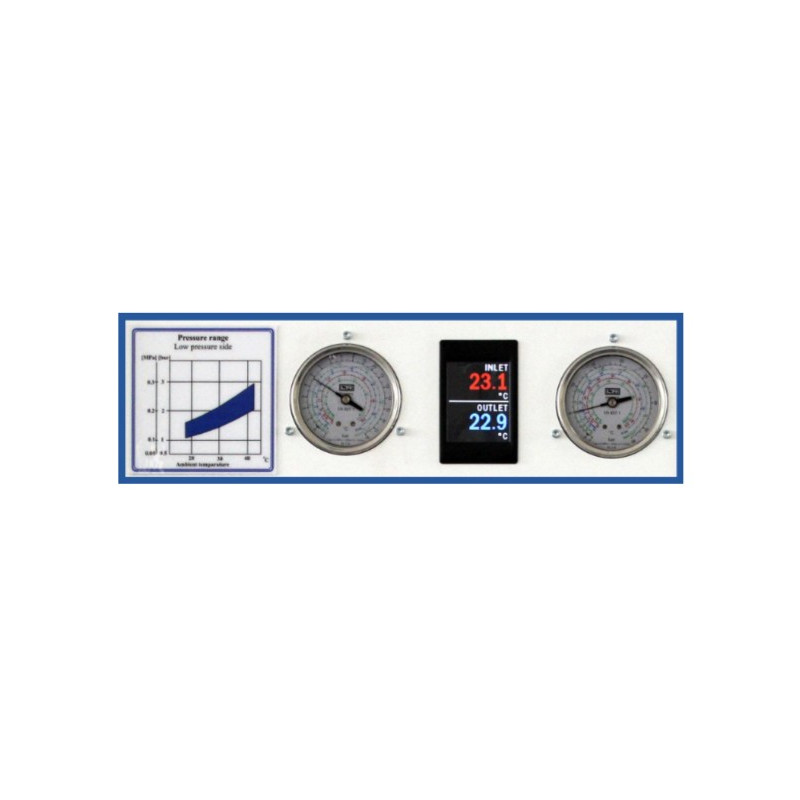

• With installed pressure gauges it is possible to monitor the pressure distribution of R134a refrigerant in the high and low pressure sides (circuits)

• Visible HVAC (heating, ventilating and air conditioning) mixing unit with its operation modes

• Visible the operation of air flow flaps

• Ability to monitor and control changes to the parameters of each system component:

- The air flow fan speed

- The air flow flap positions

- The interior (inside) temperature

- The refrigerant R134a pressure changes depending on the speed of the cooling radiator fan

- The rate of the temperature change depending on the speed of the air flow radiator fan

- The air flow flap position according to operation modes: defrost, air recirculation (fresh air) or footwell

• The training board has a diagram with LED‘s which shows the operation modes of the outlets and flaps

• The training board has a complete electric wiring diagram with built - in banana plug jumpers for measurements and simulation of the system fault codes

• Ability to simulate more than 15 system faults by disconnecting banana plug jumpers. Ability to monitor the changing operation mode of each system component;

• The training board has an integrated TFT voltmeter. It displays voltage of electronic system components:

- G92 Control motor potentiometer for temperature flap

- G114 Control motor potentiometer, footwell/defroster flap

- G112 Control motor potentiometer, central flap

- G113 Control motor potentiometer, air flow flap

- G89 Fresh air intake duct temperature sensor

- G191 Vent. temperature sender, center

- G192 Vent. temperature sender, footwell

- G17 Ambient temperature sensor

• The integrated TFT thermometer displays the temperature change depending on the pressure of the refrigerant R134a.

• The stand has a closed structure – internal wiring is not visible

• Power supply: 220V

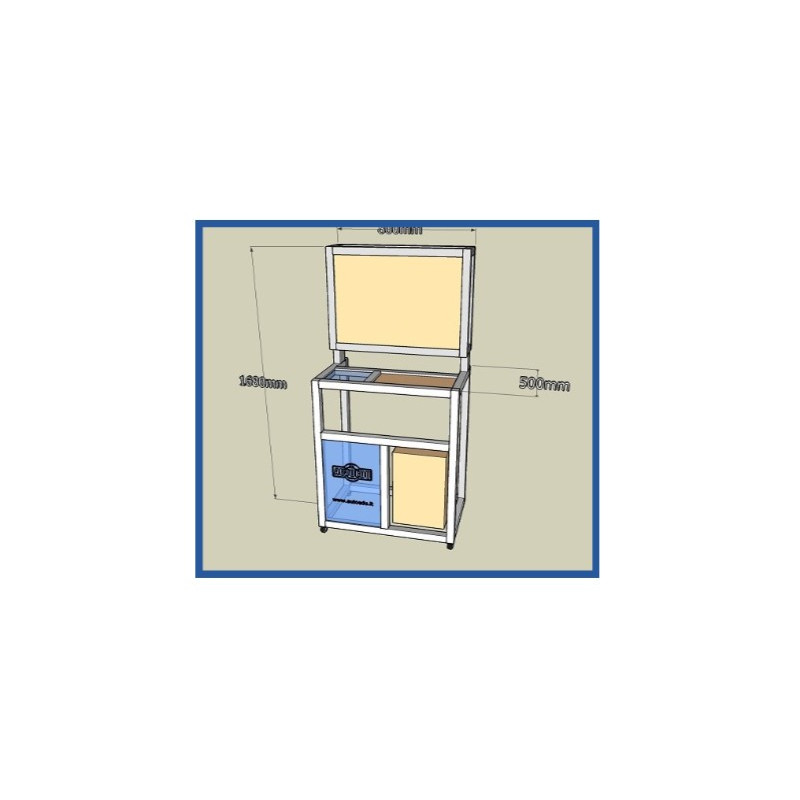

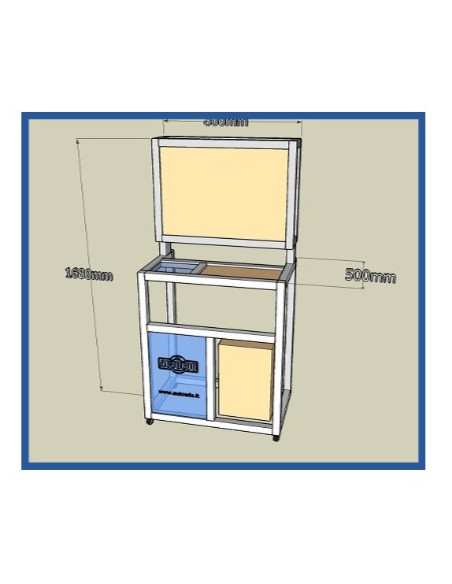

• Dimensions approx: (H x L x W): 1680 x 800 x 500 mm

• Nett weight approx: 100 Kg

• Made in Lithuania

• CE certificate

- Category

- Automobile-Automotive

- Function

- Air Conditioning