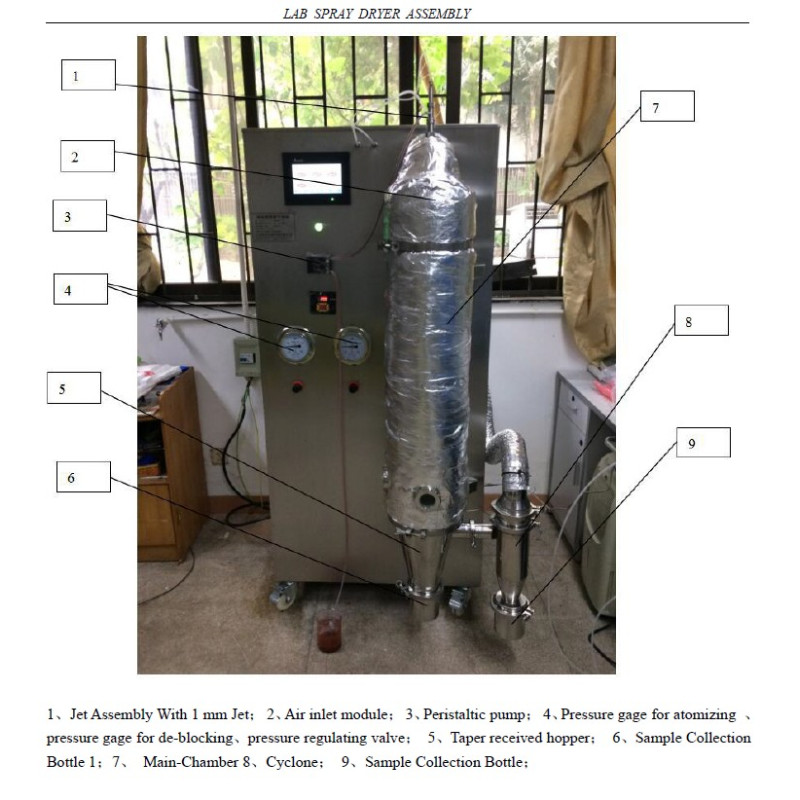

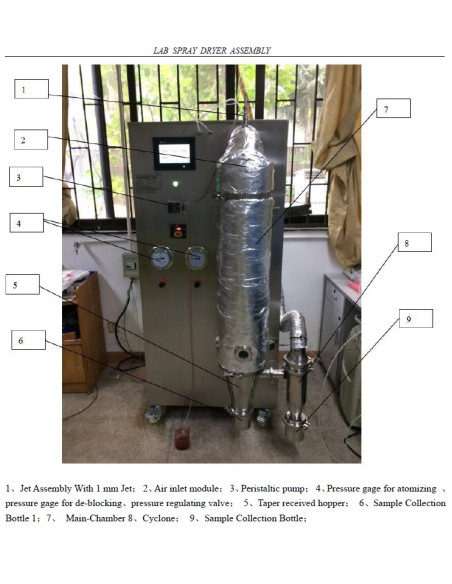

SD-8 Mini Spray Dryer

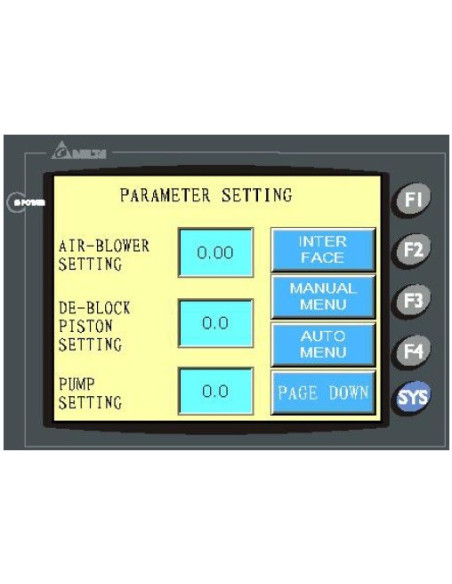

Two modes of Operation: Automatic-mode, and Eye-monitored mode for the purpose of easily controlling experimental process.

PLC controller, LCD touch panel control fascia with flow path of system.

Using proface touchable interface display operation, operator can control temperature, airflow volume, air pressure,pump speed and de-blocker frequency.

Spray chamber, cyclone separator, receiving tank are all made of Borosilicate glass which can resist strong acid/alk li, high temperature.

It can work in a no-pollution and stable environment, and the whole process can be inspected. All the spare parts are easy to install and wash.

The SD-8 Laboratory Scale Spray Dryer dryer is self contained & supplied complete and ready for immediate operation.

All major components are housed within a stainless steel cabinet and the unit can be used on a bench top or with an optional stainless steel

stand.

The system was designed on a stand to be run by a keyboard and conducted by a colorful crystal screen of touch guidance mode.

It allows 2 Run modes: Automatic-mode and Eye-monitored mode for the purpose of easily controlling experimental process .

.jpg)

► Power 5500W

► Voltage 220V, 50/60 Hz

► Atomizer material SUS 316 Stainless Steel

► Evaporating capacity 4L/H for water

► Airflow 0-330 m3/h

► Max. Input temperature 350°C

► Heater power 5000W

► Temperature precision ±1°C

► Spray gas 4.2m3/h, 2-5bar

► Nozzle jet 0.7mm standard/(0.5/0.75/1.0/1.5/2.0mm available)

► Nozzle type Two fluid nozzle

► Possible particle size range 5-100µm

► Operation mode Automatic/Manual

► Max. Sample feed 4000ml/hr

► Minimum sample volume 100ml

► Seal of cyclone/cylinder Silicone

► Deblocking Automatic

► Dimensions 950X750X1700mm

► Weight 160kg

● Spray drying can be used in a wide range of applications where the

production of a free-flowing powder sample is required.

This technique has successfully processed materials in the following areas:

● Beverages

● Flavours

and Colourings

● Milk and Egg Products

● Plant & Vegetable Extracts

● Pharmaceuticals

● Heat Sensitive Materials

● Plastics

● Polymers and Resins

● Perfumes

● Ceramics and Advanced Materials

● Soaps and Detergents

● Blood

● Dyestuffs

● Foodstuffs

● Adhesives

● Oxides

● Textiles

● Bones, Teeth and Tooth Amalgam and many others.

Most solutions and suspensions can be spray dried providing that the resulting product has the characteristics of a solid material.

- Instrument for:

- Hospitals, Lab's, Clinics

- Function:

- Spray Dryer

You might also like