SD-15 Laboratory Scale Spray Dryer

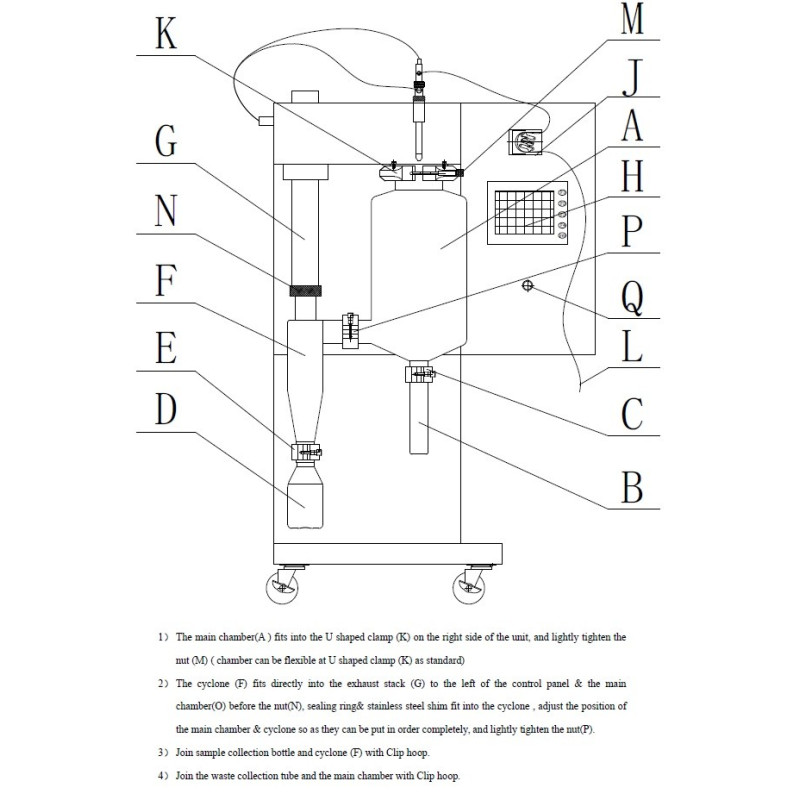

The impressive features of the Spray Dryer include its efficient performance with very short set-up times. an effective integrated nozzle cleaning mechanism and a high degree of flexibility thanks to the different cylinder geometries.

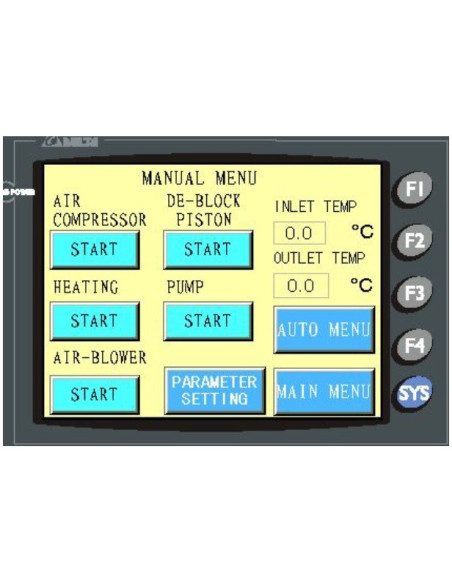

The system was designed to be stand by a keyboard, conducted by a colorful crys tal screen of touch guidance mode, and allowed two modes of run: Auto matic-mode, and Eye-monitored mode for the purpose of easily controlling ex perimental process.

- Controls & Functionality:

SD-15 mini spray dryer is designed to ensure that all func tions are simple to select & adjust, to quickly achieve the optimum conditions for spray drying. Both use a clear touch screen display, the operator can control the following func tions:

● Inlet Temperature

● Airflow Volume

● Air compressor flow

● Pump Speed

● De-blocker Frequency.

- Easy to use:

Color Touch Screen.Fast setup & cleaning times Scale up to pilot or industrial scale possible.

Visible process due to glass assembly Adjustable particle size (1-25 microns).

- Two Fluid Nozzle with SUS316L stainless steel:

The stainless steel spray assembly consists of an inner tube for the liquid sample leading to a small diameter jet. An outer tube directs compressed air to the nozzle. All units are sup plied with 0.7mm jets, other sizes are available as accessories.

The spray assembly incorporates an automatic de-blocking device that prevents the jet nozzle from becoming blocked,the de-blocking needle is activated by an integral compressor. De-blocker is some times necessary with materials which may solidify or when large particles in suspension cause blockages in the jet.

- Preparation convenience:

The minimum of materiel only needs 20-30 ml, which is convenient for dealing with small amount of sample, and it’s maximum capacity can up to 2000ml/H as well as the dealing with vast material is also very rapidly.

- Temperature protection:

The heater has an extreme high temperature when experiment fin ished, which needs air blower to continue working in order to reduce the inside temperature and ensure the safety of equipment, SD-15 spray dryer can control air blower running automatically,even the oper ator wants to tum off the air blower,the system would prevent the op erator until the temperature of system reduce to the default security state of system.

- Air compressor built-in:

Oil free compressor built-in with cushion technique, lower noise and convenient to move the dryer. Compressed air container made from the SUS 304 stainless steel to avoid vapor corrosive damage.

- Principle:

1. A menu driven micro- processor controller allows the

selection of inlet temperature, airflow, automatic deblocker frequency and pump speed.

2 . The self-priming peristaltic pump delivers the sample liquid from a container through a small diameter jet into the main chamber. At the same time an integral compressor pumps air into the outer tube of the jet which causes the liquid to emerge as a fine atomised spray into the drying chamber.

3. Heated air is blown through the main chamber evaporating the liquid content of the atomised spray. The solid particles of the material,which are normally in a free flowing state, are then separated from the exhaust air flow by a cyclone and collected in the sample collection bottle. The exhaust airflow is directed through a flexible 60 mm diameter hose direct to atmosphere or to an existing extraction system.

- Borosilicate glass or SUS 304 S.S:

Spray chamber, cyclone separator, collector are all made of Borosilicate glass which can resist strong acid/alkali, high temperature.

It can work in a no-pollution and stable environment,and the whole process can be inspected. And we can provide SUS 304 stainless steel parts. All the spare parts are easy to install and clean.

- Wide range of applications:

SD-15 mini Spray dryer can be used in

a wide range of applications where the production of a free-flow ing powder sample is required.This technique has suc cessfully processed materials in the following areas:

- Oxide, Blood, Polymers and Resins

- Beverages, Flavours & Colourings

- Milk & Egg Products, Plant & Vegetable Extracts

- Pharmaceuticals, Heat Sensitive Materials

- Plastics, Perfumes, Dyestuffs

- Ceramics & Advanced Materials

- Soaps & Detergents, Textiles

- Foodstuffs, Adhesives.

|

Model |

SD-15 |

|---|---|

|

Power |

3500W |

|

Voltage |

220V,50/60 Hz |

|

Atomizer material |

SUS 316 Stainless steel |

|

Evaporating capacity |

1.5 l/h for water |

|

Airflow |

0-330 m3/h |

|

Max. Input temperature |

250°C |

|

Heater power |

3000W |

|

Temperature precision |

±1°C |

|

Spray gas |

4.2m3/h, 2-5bar |

|

Nozzle jet |

0.7mm standard/(0.5/0.75/1.0/1.5/2.0mm available) |

|

Nozzle type |

Two fluid nozzle |

|

Possible particle size range |

1-25µm |

|

Mean Residence time |

1.0-1.5 sec. |

|

Operation mode |

Automatic/Manual |

|

Max. Sample feed |

2000ml/hr. |

|

Minimum sample volume |

30ml |

|

Spray chamber material |

borosilicate glass |

|

Cyclone separator material |

borosilicate glass |

|

Receiving tank material |

borosilicate glass |

|

Body material |

SUS304 Stainless steel |

|

Seal of cyclone/cylinder |

Silicone |

|

Compressor |

Built-in oilless |

|

Sound |

<60db |

|

Dimensions |

750x650x1200mm |

|

Weight |

110KG |

|

Display |

7-Inch LCD display for Heat, Spray, Pump, Air pressure, de-blocker frequency |

|

Thermal protection |

Blower does not stop until temp <90°C |

|

Deblocking |

Automatic |

|

Inert loop (for organic solvents) |

Optional |

- Instrument for:

- Hospitals, Lab's, Clinics

- Function:

- Spray Dryer

You might also like